BOTTONI PRODUCTS

Roasters

Coffee roasters are machines used to roast coffee beans, giving them their characteristic dark brown color and typical intense aroma, making them ready to be ground and used to prepare coffee-based drinks.

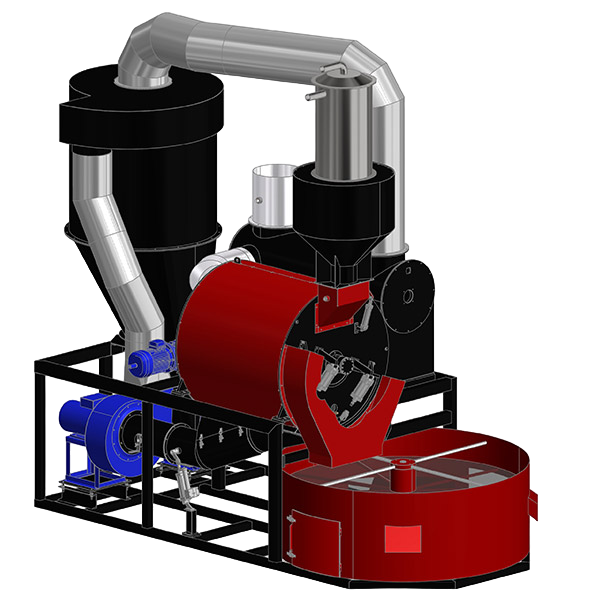

BTR roasters

BTR roasters are machines with combustion chamber separate from the roasting drum; this technology allows the better management with the recovery of thermal energy from the roasting drum (see recirculation system) and consequent energy saving.

Characteristics

Our roasters are all equipped with:

- Roasting control system automatic, semi-automatic, manual

- Cooling fan enhanced tub

- Manual control for unloading roasted coffee from the drum to the tub in the event of a power failure

- Film recovery cyclone complete with rotary valve

- Dust recovery cyclone mounted on the tank cooling air expulsion line

In the new roasters we install inverters to regulate the revolutions of the drum and an inverter to regulate the flow of hot air required for roasting.

Integrated system for a energy savings of 20/25 %.

Heat input system

We have designed and patented the heat inlet in the rear part of the drum, in this way the hot air from the combustion chamber enters and is distributed more evenly enveloping the beans during roasting

In all BTR machines there are two cyclones, one for the recovery of the dust coming from the roasting process and a second one for the dust present in the tank cooling air.

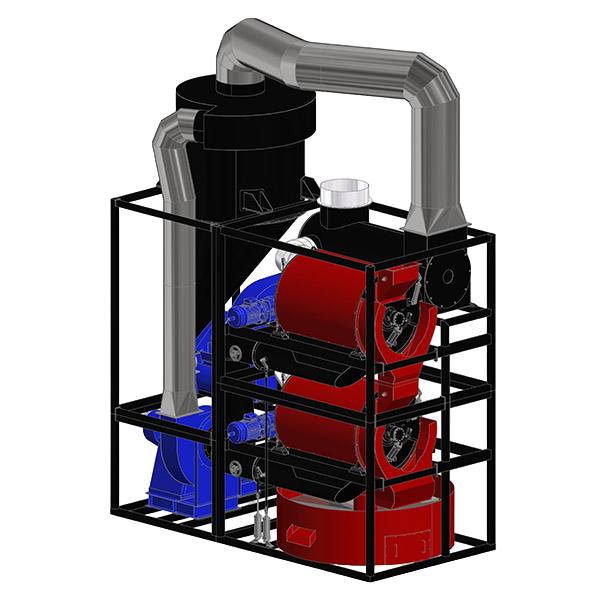

BTRV roasters

The BTRV roasters, unlike the BTRs, are equipped with 2 roasting drums.

The advantages are:

- Reduction of toasting times through the realization of short cycles and more frequent drains (about 5-6 minutes compared to 12-15 minutes)

- Reducing the weight loss of coffee through an optimization of the heat exchanges

- Full automation of the process, achieved through the insertion of electronic sensors capable of piloting both mechanical (loading/unloading) and thermal (supplying/subtracting heat) interventions energy saving (around 30 %) compared to conventional machines.

With this type of roasting process it is possible to respect all 3 roasting phases (dehydration, heating and pyrolysis) precisely because it is carried out in 2 stages so that the characteristic phenomena of roasting proceed in succession. In the first drum, the quantity and method of administering the heat are such as to produce only dehydration and heating of the grains. The actual roasting takes place in the second drum, for which the thermal requirements are quite specific.

The separation in two stages allows a greater possibility of controlling the whole process and therefore, an improvement of the production in all aspects

BTRV roasters are supplied on specific customer needs.

For information, specifications and/or any information, send an email to info@bottoimpinati.it

Smoke recirculation and abatement system

The coffee roasting process inside the drum takes place by conveying into it, via a so-called recirculation fan, a flow of hot air generated in the combustion chamber.

Leaving the drum, this still hot air flow (and with it the organic substances released by the coffee during the cooking phase) is largely conveyed back to the combustion chamber to return to the right temperature and return to the drum; so only a small part of the hot air is evacuated into the atmosphere.

The administration of heat during the roasting phase is a very important factor; for medium-small roasters it is recommended / possible to install two-stage burners or progressive bi-stage while for medium-large and automated machines it is advisable / necessary to install adjustable modulating burners over the entire thermal curve; these have the necessary potential to perform the two main functions:

- Warm the air at the temperature required for the roasting process;

- Allow the removal of organic substances released from the process.

To summarize, a fan generates a recirculation of air which heats up in the combustion chamber, transfers the heat into the drum and transfers it to the product, from here it flows into a cyclone (film container) to deposit the heavy substances and returns to the combustion chamber again to recover the necessary thermal energy to be transferred back into the drum.

The main advantages of this system are:

- Only excess air which has already undergone the process of reducing organic substances is conveyed to the outflow chimney into the atmosphere;

- The presence of a single burner for the two functions;

- The integrated recirculation allows energy savings of 20 – 25 % compared to traditional roasting machines.

NB: the process is almost always managed and controlled via the automatic roasting control system described in the following paragraph.

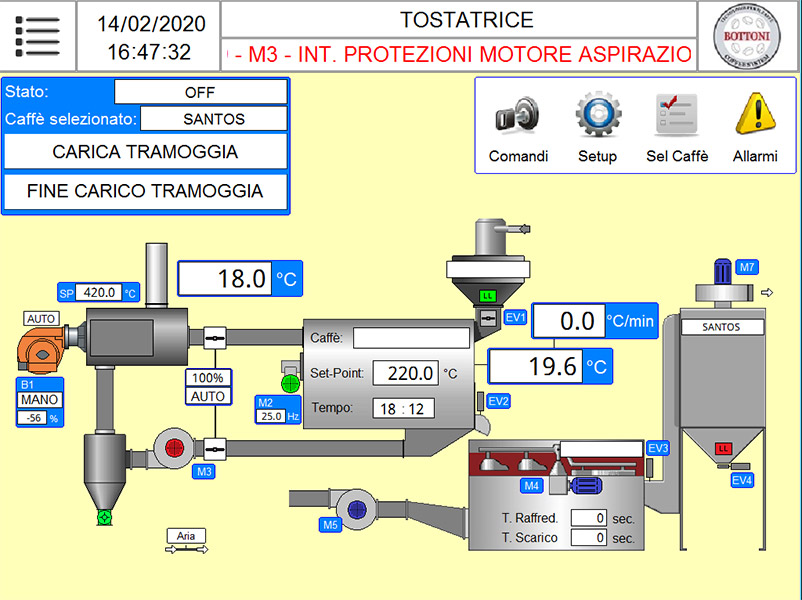

Automatic toasting control system (optional)

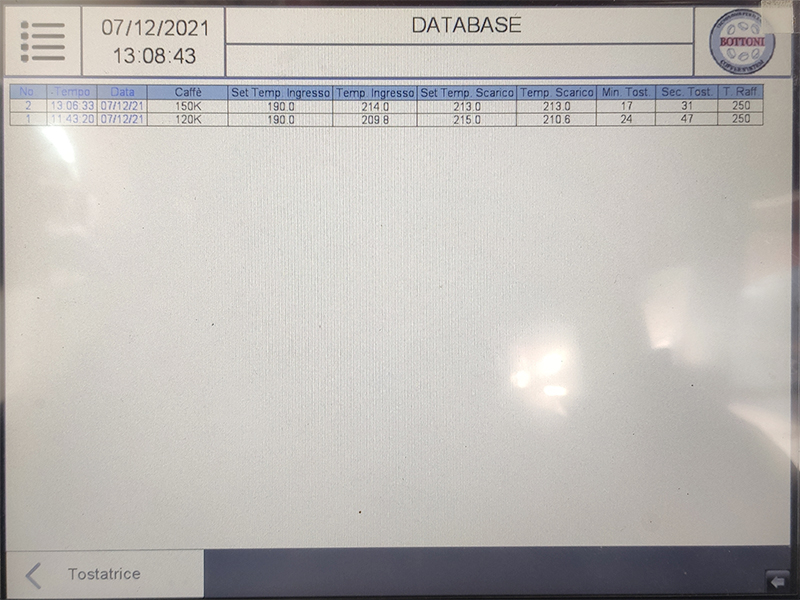

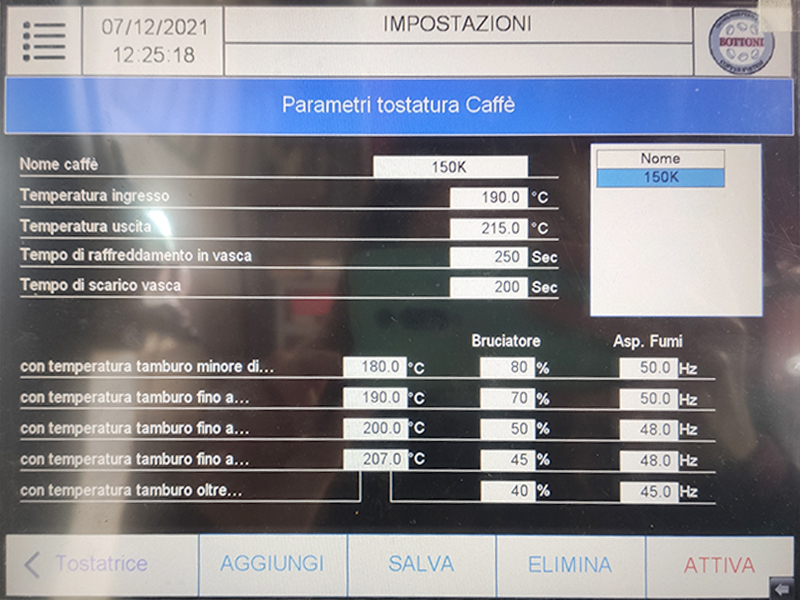

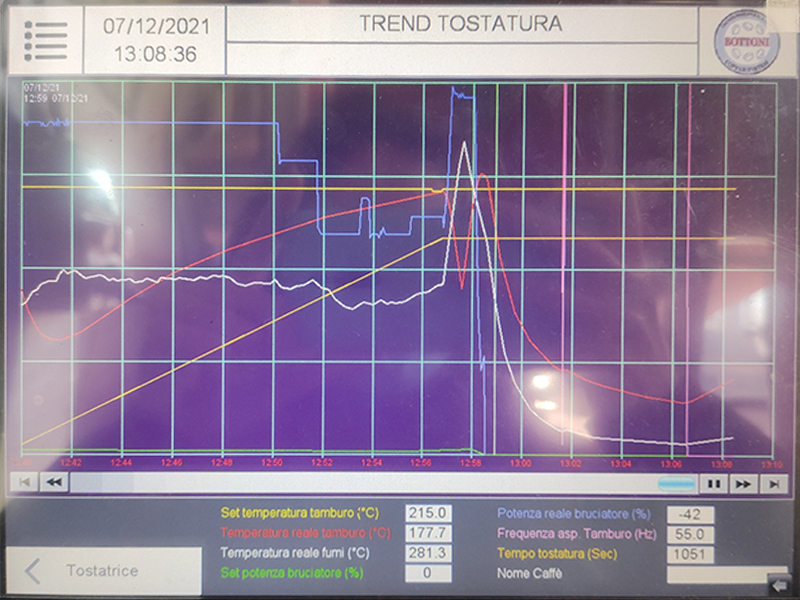

BTR automatic roasters can be managed by a control system, which allows you to set and match certain parameters to the various types of coffee to be roasted (blend or single origin); the parameters mainly concern the time and temperature values with which to build specific roasting profiles (otherwise, program or roasting curve).

The other parameters (from the loading of the green coffee to the unloading of the destoner and beyond) allow the repeatability and conformity of the roasting process; of course the values can be changed whenever you want.

The system diagnoses, detects and warns of any anomalies.

The control system software, as mentioned, it can be installed on a touch screen panel or on a personal computer. The touch screen panel is less direct than the PC, but it is still an excellent tool, cheaper and less bulky being installed on the control panel.

The control software also includes the possibility of manually managing some individual functions or utilities (for example the unloading of the green coffee hopper, of the drum, of the cooling tank, etc...) while for guarantee and safety reasons the commands of the burner and heat flow control valves.

The PC compared to the touch screen panel the guarantees a wider management of the roasting process both for memory capacity and for graphical representation.

Furthermore, the control system is set up for connection to an ethernet network (to be able to access the internet) through which it will be possible to use the remote assistance service.

TECHNICAL DATA

| Roaster | Kw | Kcal/h | MEASURES | PRODUCTION CAPACITY | Fuel | ||||

| Height cm | Length cm | Weight kg | kg/cycle | Toasting time | Hourly production of green coffee | ||||

| BTR 5kg | 4 | 7.500 | 180 | 100 | 250 | 5 | 13-18 mins | 20kg | LPG/CNG/Diesel |

| BTR 15kg | 6 | 22.500 | 200 | 130 | 300 | 15 | 13-18 mins | 60kg | LPG/CNG/Diesel |

| BTR 30kg | 8 | 45.000 | 200 | 160 | 400 | 30 | 13-18 mins | 120kg | LPG/CNG/Diesel |

| BTR 60 Kg | 10 | 90.000 | 280 | 180 | 1.200 | 60 | 13-18 mins | 240kg | LPG/CNG/Diesel |

| BTR 120 Kg | 16 | 180.000 | 320 | 200 | 1.800 | 120 | 13-18 mins | 480kg | LPG/CNG/Diesel |

| BTR 240 Kg | 25 | 360.000 | 380 | 250 | 2.400 | 240 | 13-18 mins | 960kg | LPG/CNG/Diesel |

BOTTONI PRODUCTS

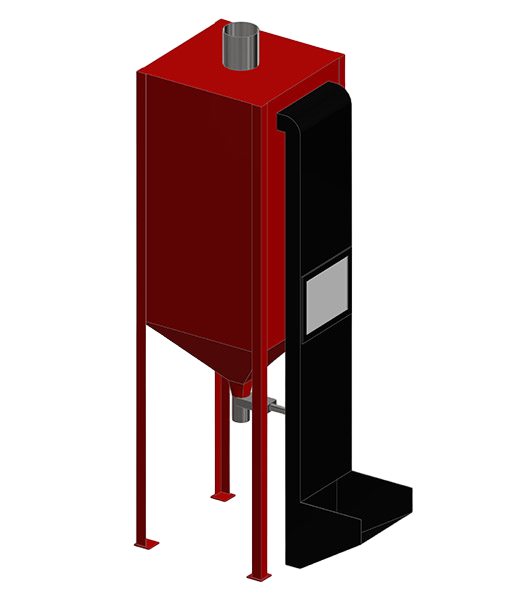

Silos

Coffee silos are devices used to store and preserve roasted coffee beans in large quantities, they are designed to keep the coffee fresh and protected from air, light and humidity, thus ensuring that the coffee retains its original aroma and taste .

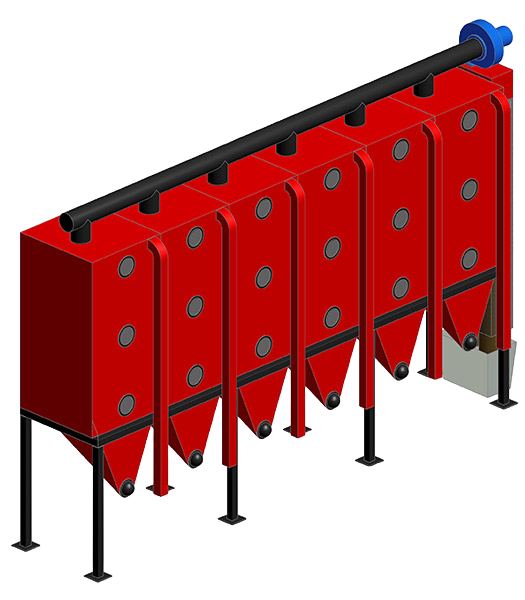

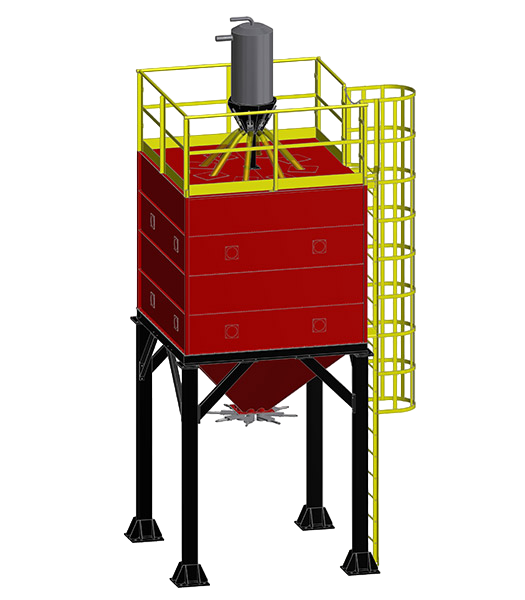

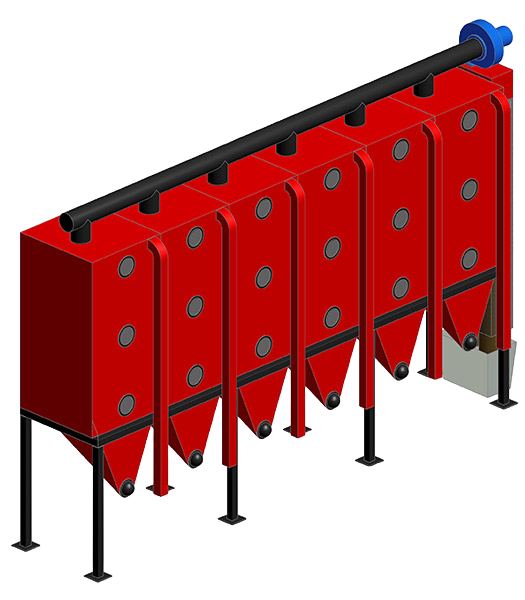

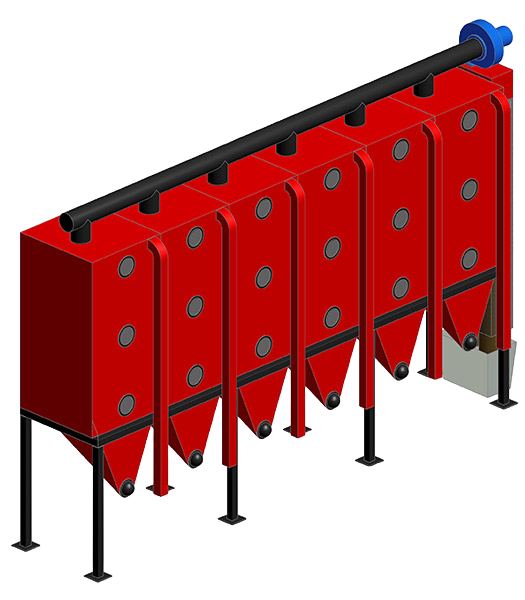

Green Coffee Storage Silos

Green coffee storage facility starts from the unloading of bags or big bags or containers with different solutions:

- Weighted hopper of adequate capacity

- Continuous weighing system

The green storage silo includes:

- Loading via a suction system with dust recovery system

- Rotary-motorized distributor

- Possibility of dividing the silo into 2-4-6-8-10 sectors

- Unloading through pneumatic vents or electro-pneumatic

- Waste hopper on weighing cells

The silo has a cubic module shape, this allows to increase the capacity according to the height of the building, ease and speed of installation at the customer's premises and practicality in transport. Ability to install min / max levels for each sector

Green coffee storage management can be entered in our automation software and manage batch traceability and product stock.

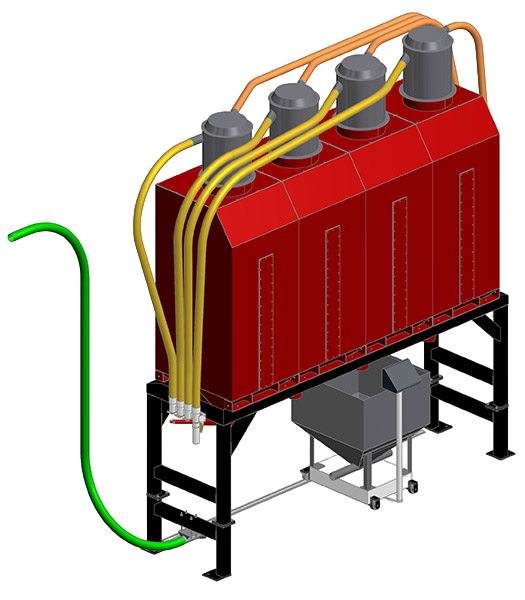

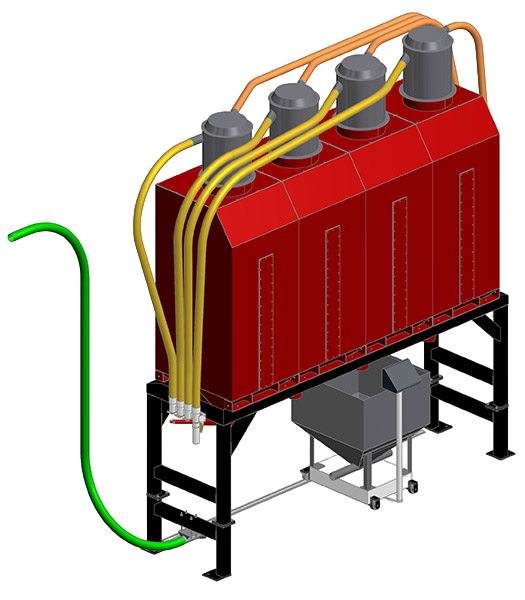

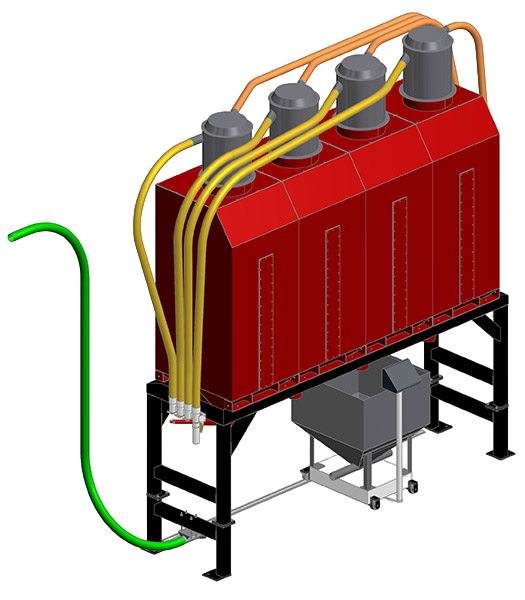

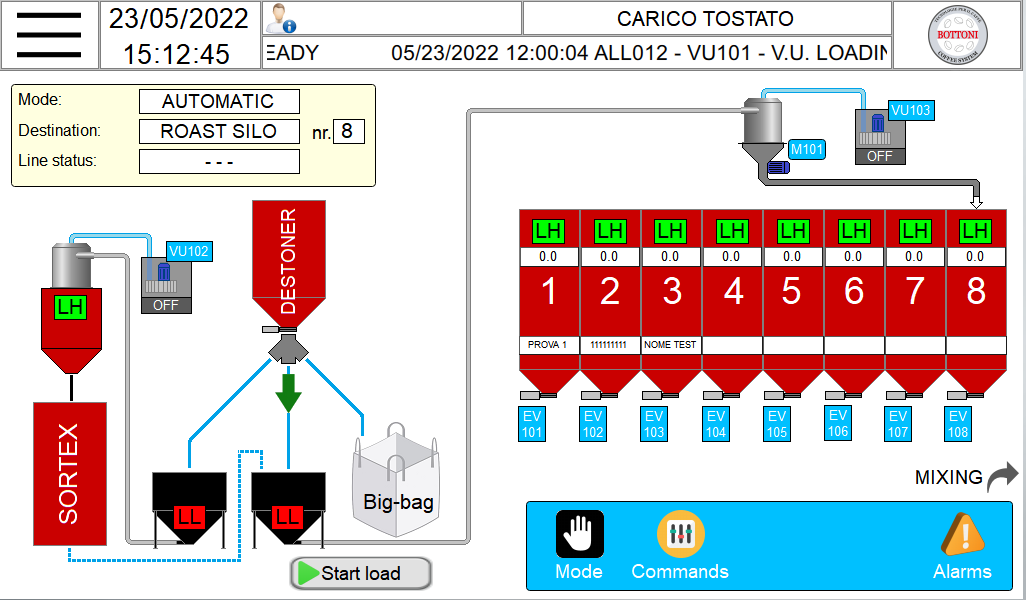

Roasted Coffee Storage Silos

Following the roasting process, the coffee is directed to the roasted coffee storage silo, which is complete with:

- Loading of the silos through the suction system

- Distributor rotary–motorised;

- Breakage system some grains

- Ability to install min / max levels for each sector

- Possibility of dividing the silos into 2-4-6-8-10 sectors

- Unloading through pneumatic vents or electro-pneumatic

- Unloading hopper on weighing cells or discharge into weighed blender to formulate blends

The silo has a cubic module shape, this allows to increase the capacity according to the height of the building, ease and speed of installation at the customer's premises and practicality in transport;

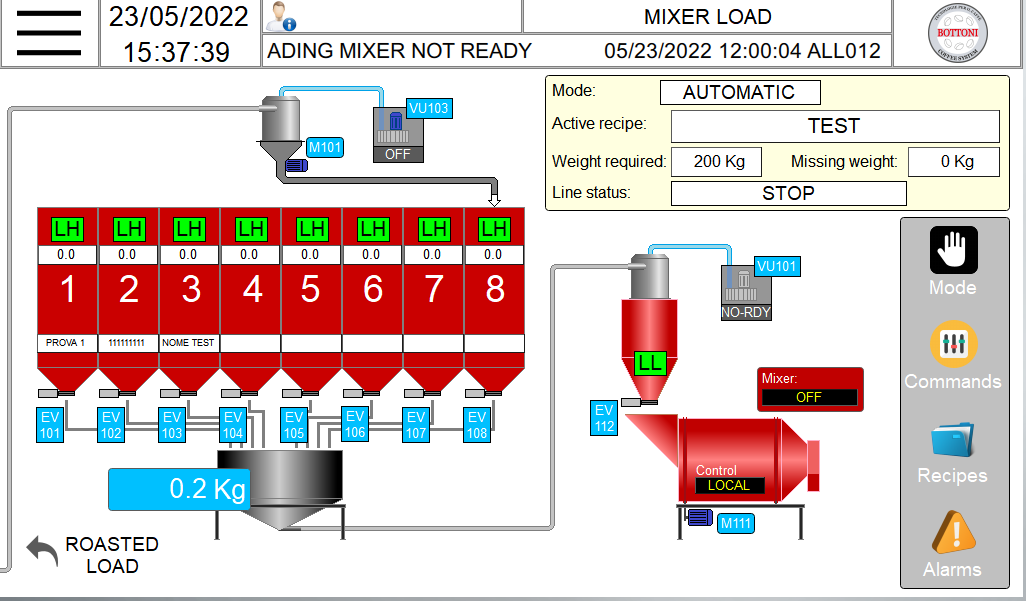

The roasted coffee storage silos can be integrated into ours automation software and manage batch traceability and the stock of the product in the silos, it is also possible to set and save the creation of the blends.

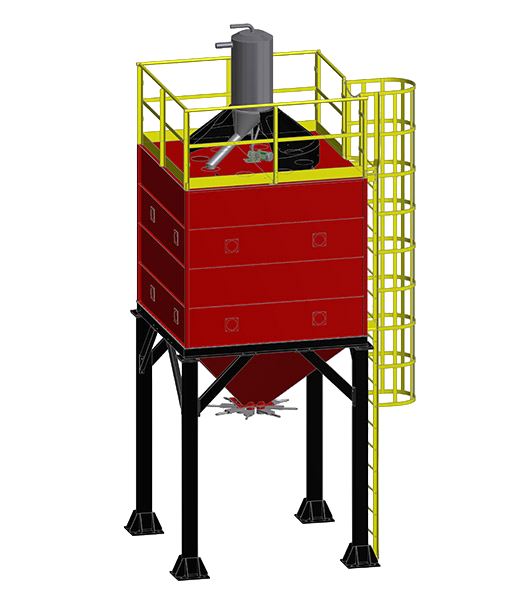

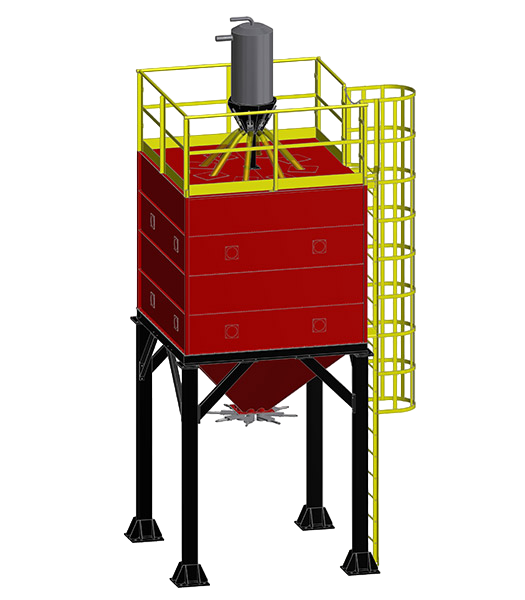

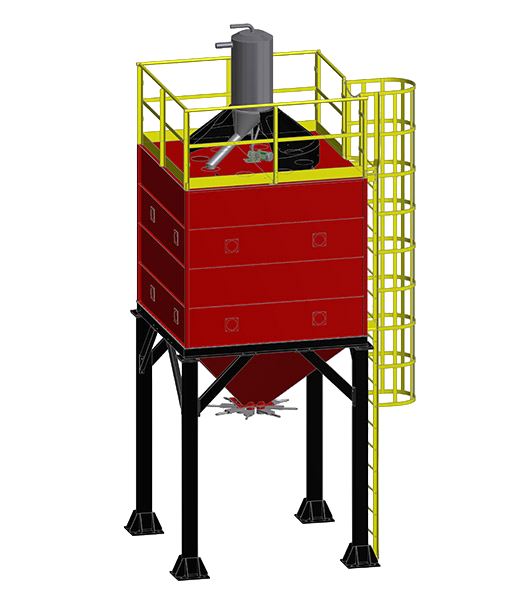

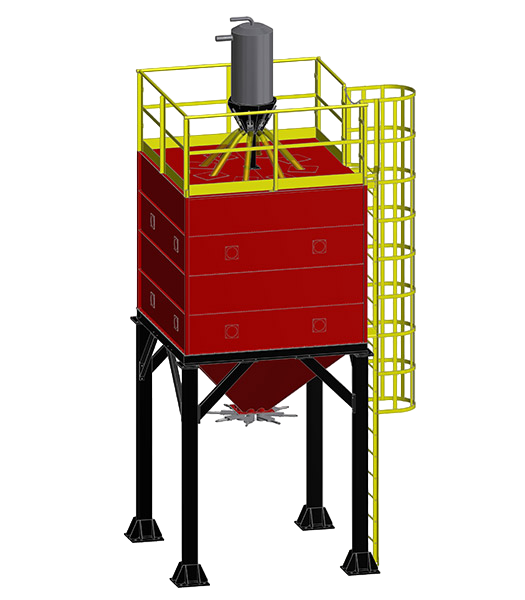

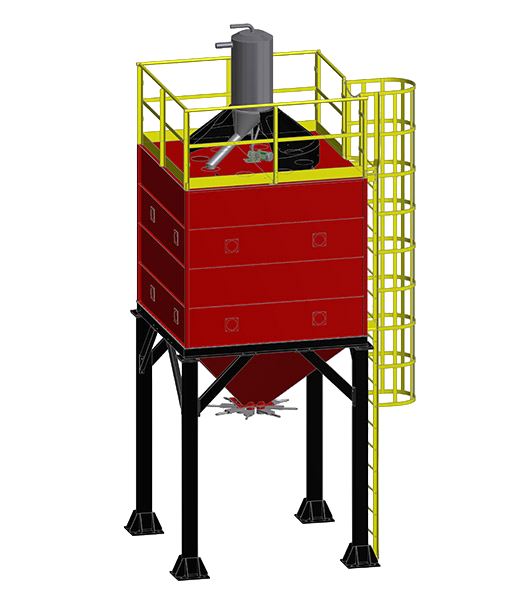

Ground Coffee Storage Silos

We design and manufacture degassing silos for ground coffee, with shape and size on customer request.

Possibility of integration to the automation software

The silos are equipped with:

- Loading of the product in suction op by auger

- Ability to install min / max levels for each sector

- Product unloading via colcea

NB we can supply different solutions for coffee grinding

Management software

Our Silos can be managed by a control system

The automation software can:

- Manage traceability of lots

- Manage inventory of the product

- Set up and save the creation of blends

Furthermore, the control system is set up for connection to an ethernet network (to be able to access the internet) through which it will be possible to use the remote assistance service.

BOTTONI PRODUCTS

Accessories

Our industrial coffee brewing accessories are designed to improve the efficiency and quality of your brewing process, ensuring perfect coffee brewing with every use.

Destroner

The destoner is a machine capable of separating the stones from the roasted coffee thanks to the two different specific weights. Is formed from:

- Hopper connected to the tank drain;

- Sheet metal container;

- Feet for fixing to the ground, on cells or on wheels;

- Coffee suction fan.

The measures and the capacity are variable according to the customer's needs.

Heat exchanger

The system consists of:

- An independent combustion chamber for the production of the hot fluid (combustion products) with a special design for heat recovery;

- A stainless steel tube bundle on the clean side of which ambient air is conveyed which captures heat and conveys it to the product (in the roasting drum);

- A medium prevalence fan for movement of ambient air;

- An adequate insulation system to obtain the best performance.

The products developed in the combustion chamber pass through the tube bundle releasing heat to then be conveyed outside.

The fan moves the ambient air making it pass in a first phase beside the combustion chamber with the dual task of capturing heat and participating in the insulation function.

After which the already partially hot air is conveyed to the clean side of the exchanger where, thanks to a particular flow round, it captures the heat necessary for the roasting process and transmits it to the product in the drum.

Burner and temperature regulation are automated by means of valves and compatible instrumentation.

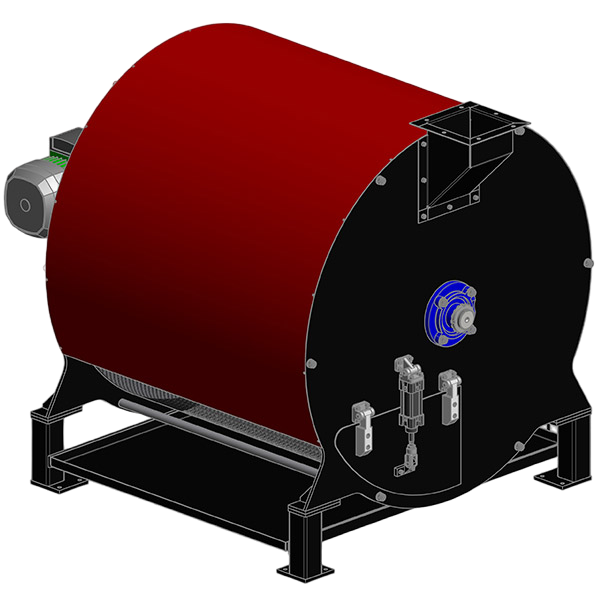

Mixer

The mixer is a machine for formulating coffee blends. It can be used both for blending different types of green coffee and for blending roasted coffees.

It can be equipped with weighing cells and is complete with:

- Gear motor

- Product receiving hopper

- Waste hopper

- Electrical cabinet

| MIXER TECHNICAL DATA | |||||

| Capacity | ø Drum cm | Length cm | Width cm | Height cm | Drum revolutions/min |

| 100kgs | 900 | 1330 | 990 | 1095 | 10 |

| 120kg | 900 | 1530 | 990 | 1095 | 10 |

Smoke burners

The smoke burner is an apparatus that allows the complete combustion of the gases coming from the roasting process and of any residual solid particles that they carry after having left them in the film container.

The cavity is covered with ceramic fiber.

The temperature of 700°C is reached in the combustion chamber by means of a burner.

The fumes to be burned enter from the lower part and during the crossing they are hit by the dart that the burner generates. The exit of the product from the combustion thus completed takes place through an opening located in the upper part of the stove and of a suitable diameter.

Each smoke burner will have different dimensions and power based on the model of the toaster.

We supply smoke burners both for roasters of our production and for roasters of other brands.